The barbecue grill is one of the highlights in external or internal areas of a residence. For being an attractive element while composing as the center piece of decoration, the barbecue grill deserves a special attention from architects.

Granite is an excellent option of barbecue grill covering, it is a material with high resistance to the heat from fire and fat. Even though the material has high resistance, we advise to clean the granite as soon as possible when some kind of product or fat falls on it. In addition to that, this natural stone provides sophistication and elegance to the environment.

Should I use light or dark color in barbecue grill covering?

Although the granite is a resistant material for the barbecue grill, it is recommended to use dark shades, because they are more efficient against stains from agents like fats and drinks. However, if you want to use light colors of granite, it is indicated to waterproof the stone and do maintenance periodically.

Cleaning

Another advantage of barbecue grill covering with granite is the simplicity of cleaning due to its smooth and uniform surface. Neutral detergent and wet cloth are enough to clean. It’s worth pointing out that abrasive products as steel wool are not recommended because it makes the stone lose its natural shine throughout time.

Granite colors

It is necessary to choose carefully the color of granite so that there is harmony with the environment. When it comes to barbecue grill covering, the black and brown colors are the most popular. Beyond conveying elegance, these colors match with all colors and forms of other decorations from the environment.

Check below some options of colors for barbecue grill covering with granite:

Absolute black

This is a model with an intensive color and presents lower porosity, which makes it very popular for barbecue grills. Its tonality helps to hide little dirt and prevents absorption of agents that can stain the stone.

Black San Gabriel

As well as Absolute Black, the Black San Gabriel is one of the most popular in the market. It composes well with woody elements and with white and gray colors.

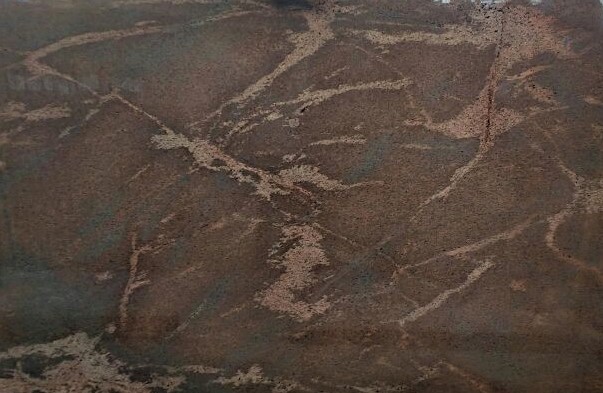

The dark brown color is also a versatile option, because the decoration in external residence areas tends to be in beige tones. Besides that, the brown is not obvious and traditional, which transmits authenticity to the project.

Brown tabaco

The model is characterized by an intensive brown color with small black spots.

Imperial Coffee (PR Group own quarry)

The Imperial Coffee is known by its brightness and mixture of dark colors, which transmits sophistication, warmth and sobriety to the environment.

There are other models of granite that offer a variety of compositions in different projects, making it possible to apply from rustic to the most sophisticated decoration.

Check out all the options of granite colors available on products webpage from PR Group Paraná and give a touch of elegance to your project!